Diffractive Beam Splitters: Your Smart Solution for Laser Beam Management

If you’ve ever tried splitting a laser beam into multiple beams and didn’t get the results you wanted — uneven energy, bulky system, lost precision — you’re not alone. Managing high-precision laser beams isn’t easy, especially when your project demands perfect consistency across every spot.

Diffractive Beam Splitters can actually fix those headaches — but only if you choose the right one and know how to use it properly.

In this article, I’m going to walk you through everything you need to know: what diffractive beam splitters, also known as phase diffraction gratings are, why they’re important, how they work, and what you should watch out for when dealing with optics, lasers, and wavelengths.

Stick with me, and by the end, you’ll know exactly how to get better control over your laser beams — no more guessing or hoping for the best.

Let’s jump in.

What Exactly Are Diffractive Beam Splitters?

Diffractive beam splitters work like special tools that split one laser beam into several smaller beams and they do it in a super clean and controlled way.

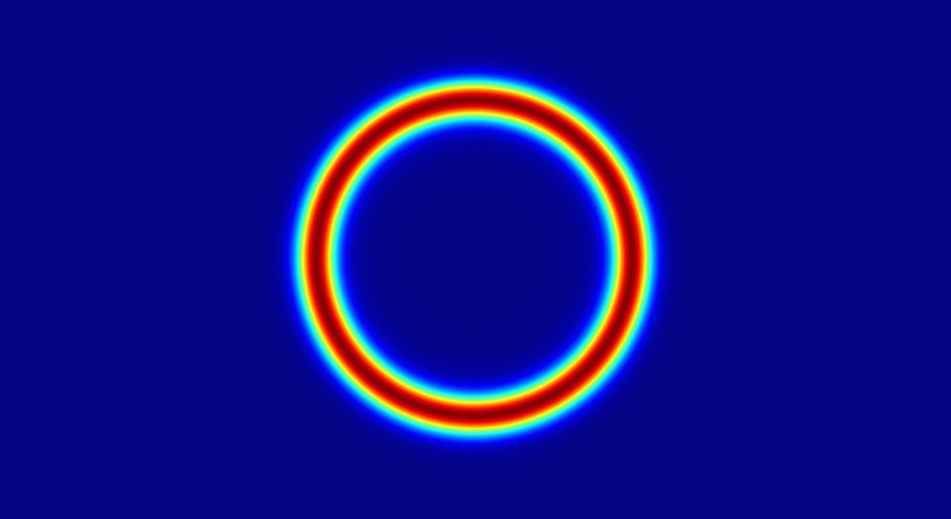

They’re not just simple mirrors or lenses. They use something called diffraction, working with tiny micro-patterns on their surface to bend and split the light just right.

Instead of spreading the laser’s energy all over the place (like a flashlight), these splitters create a fan of beams exactly where you want them.

It keeps the energy balanced, the pattern organized, and the whole system working smoothly.

Basically, it’s like taking one powerful laser and creating a well-trained team of mini-lasers.

How Do Diffractive Beam Splitters Work?

Diffractive beam splitters are something called a phase diffraction grating. These fine periodic structures bend and separate the laser’s light into different directions based on the light’s wavelength and the grating period, with no sensitivity to polarization.

Here’s a simple way to think about it:

-

The grating has tiny patterns that “trick” the laser into splitting up.

-

The way the patterns are shaped controls how many beams you get and where they go.

-

The right design keeps the intensity even across all the beams.

It’s a precise dance between optics, laser physics, and diffraction, and when it’s done right, you get incredible accuracy without wasting power.

Why Wavelength and Focus Optics Matter

One thing many teams run into when they first start using diffractive beam splitters: If you don’t match the splitter properly to your laser’s wavelength and to your focusing optics , your results will be disappointing. (Think defocused beams, a strong central spot, or wrong angles.)

That’s why it's so important to:

-

Know your laser’s exact wavelength.

-

Understand the focus optics, especially the field size they support.

-

Choose or design a splitter that matches your setup perfectly.

Skipping this step can lead to a lot of frustration — and expensive fixes later.

Where Diffractive Beam Splitters Shine

You’ll see diffractive beam splitters making a real difference in places like:

-

Laser materials processing (perforation, welding, drilling)

-

Medical laser systems (fractional skin treatment)

-

Laser-based measurement and metrology

-

Optical testing and calibration

-

Micromachining and lithography (parallel scribing, oxide and copper ablation)

Basically, anywhere you need consistent, clean, multiple beams from a single laser source — this is your go-to solution.

What to Look for When Choosing a Beam Splitter

If you’re searching for the right diffractive beam splitter, don’t just grab the first one you find.

Smart teams look for:

- Compatibility with their laser wavelength.

- Suitable for the system focusing optics.

- Durable, high-quality optical elements that hold up under power.

- Diffraction efficiency that is suitable for the application.

Custom solutions might also be worth considering if your application is very specialized.

Final Thoughts

Working with lasers at the professional level means you can’t afford guesswork.

Diffractive Beam Splitters are incredibly powerful tools when used correctly — delivering precision, control, and efficiency to your optical systems.

Choosing the right splitter, based on a correct phase diffraction grating, suitable for your laser specs and focusing optics, will make a huge difference in your system’s success.

Better beam control means better results, higher throughput and smoother operations.

If you need help finding the right diffractive solution for your project, don’t wait — reach out for expert guidance and get it done right the first time.

FAQs.

1. What does a diffractive beam splitter actually do?

It splits a single laser beam into multiple beams in a controlled, predictable way using special micro-structured optics.

2. Why do I need to match the beam splitter to the laser wavelength?

Because if the wavelength and splitter don’t match, you’ll get uneven energy, wrong angles, and poor diffractive efficiency — ruining the application.

3. How can I find the best diffractive beam splitter for my system?

The best way is to get expert advice based on your laser type, wavelength, and application — contact a specialist today and make sure your setup is spot-on!

Comments (0)